Application

Wires and fibers - fields of application

Field of application - laying wires

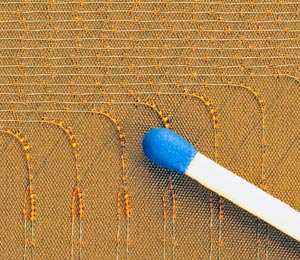

The laying of wire is an essential part in the production of many products from all spheres of life today. Laying wire with ZSK's Technical Embroidery Systems is cost efficient, more reliable and environmentally friendly.

One of todays most innovative fields of activity is the embrodering of antennas (RFID) and sensors on textiles. Without any damage of the textiles characteristic signals like fill level, movement or temperature can be measured and relayed. Laying wire with ZSK's Technical Embroidery Systems can be found at many other fields of application.

Exemplary products amongst others are:

- heated working- or outdoor clothing

- luminous textiles to improve security or comfort

- heated steering wheels

- heated car seats

- embroidered circuits, to integrate electrical functions into clothing

- infrared heating systems

- protective systems for safes

- electromagnetic shielding for tap-proof chambers

Field of application - laying fibers

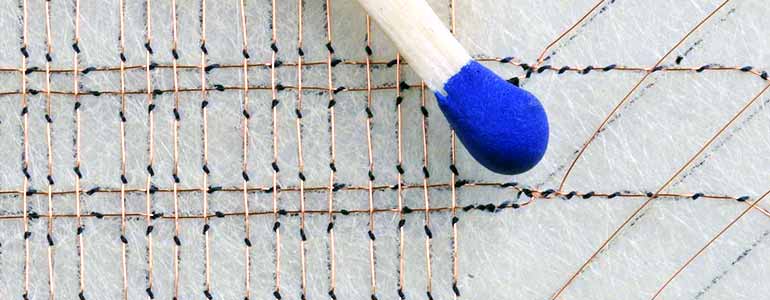

A radically new technology to built up reinforcement fabrics is the free orientation, placing and fixing of reinforcement materials through an embroidery machine.

It can be used in applications where the production of components or textile structures requires the stitching of variable-geometry ply stacks, where fabrics need to be reinforced locally, or where fabrics must be assembled. Various materials like carbon-, glass- and aramid fibres, wires etc. can be processed.

Single layed rovings are fixed to the base material by stitching. During the process, the base material is moved by the pantograph, enabling to lay rovings in any direction and quantity.

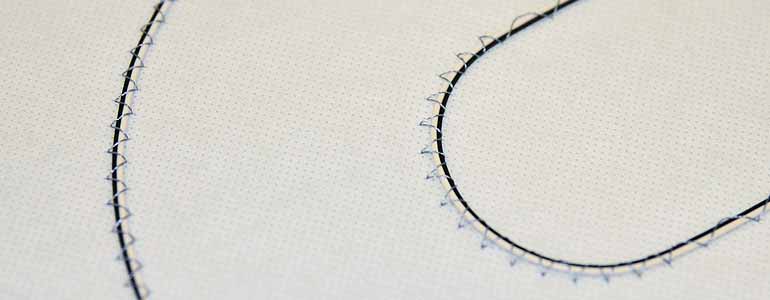

TFP - Tailored Fiber Placement

Another major advantage of this new process is to be able to lay the rovings according to the distribution of forces within a structural component.

100% reproducibility speaks for itself and is accomplished by the following:

- automatic preform production

- low mass tolerance

- high dimensional accuracy

- reliable identical laying roving

This cost effective process is driven by high stitching speed on one hand and multiple laying heads on a machine.

In comparison to other textile technologies the expensive loss of materials is kept to a minimum. Accordingly the problem of waste disposal is very little.