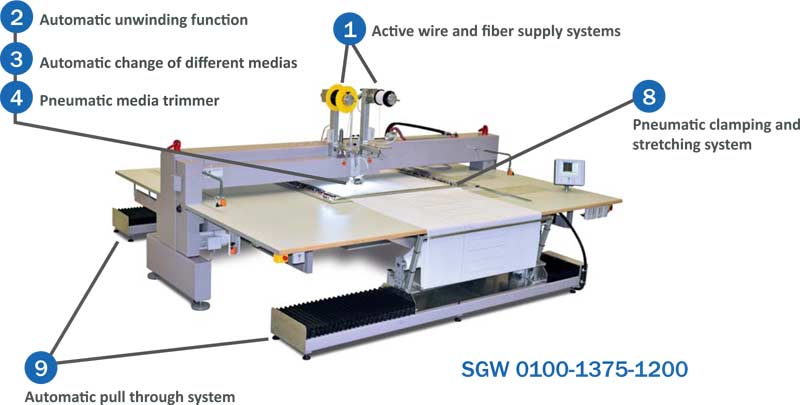

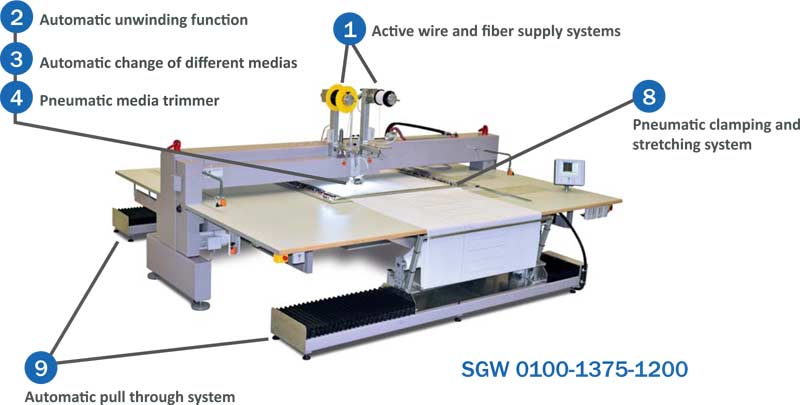

Technical Embroidery Solutions

At ZSK, we have the experience and technology to supply options for all ZSK Technical Embroidery Systems to guarantees a significant degree of automation

At ZSK, we have the experience and technology to supply options for all ZSK Technical Embroidery Systems to guarantees a significant degree of automation